Selection of weight sensors in automation systems?

Hi everyone,

In industrial automation systems, the selection and configuration of weight sensors play a crucial role in ensuring precise measurements and operational efficiency. The process involves multiple steps, from selecting the right type of sensor to configuring it within the system and regularly evaluating its accuracy. This detailed exploration will cover these aspects in a clear and comprehensible manner.

Selection of Weight Sensors

Determine the Application Requirements:

Weight Range: Understand the maximum and minimum weights that the system needs to measure. This range will directly influence the type of sensor needed.

Environment: Consider the operating environment. Factors such as temperature, humidity, and the presence of corrosive materials can affect sensor performance and longevity.

Accuracy Requirements: Determine the required accuracy and precision. Higher precision might necessitate more advanced and potentially more expensive sensors.

Load Characteristics: Analyze if the load will be static or dynamic, as this impacts the choice between static load cells and those designed for dynamic applications.

Choose the Sensor Type:

Strain Gauge Load Cells: The most common type used in industrial settings, they convert force into an electrical signal through strain gauges.

Piezoelectric Load Cells: Ideal for dynamic loads, these sensors use the piezoelectric effect to measure changes in pressure, acceleration, or force.

Capacitive Load Cells: Used for high-precision applications, they measure the change in capacitance caused by the deformation of the load cell under weight.

Hydraulic Load Cells: Best for harsh environments, they measure weight using a fluid-filled chamber whose pressure changes with applied weight.

Configuration of Weight Sensors

Installation:

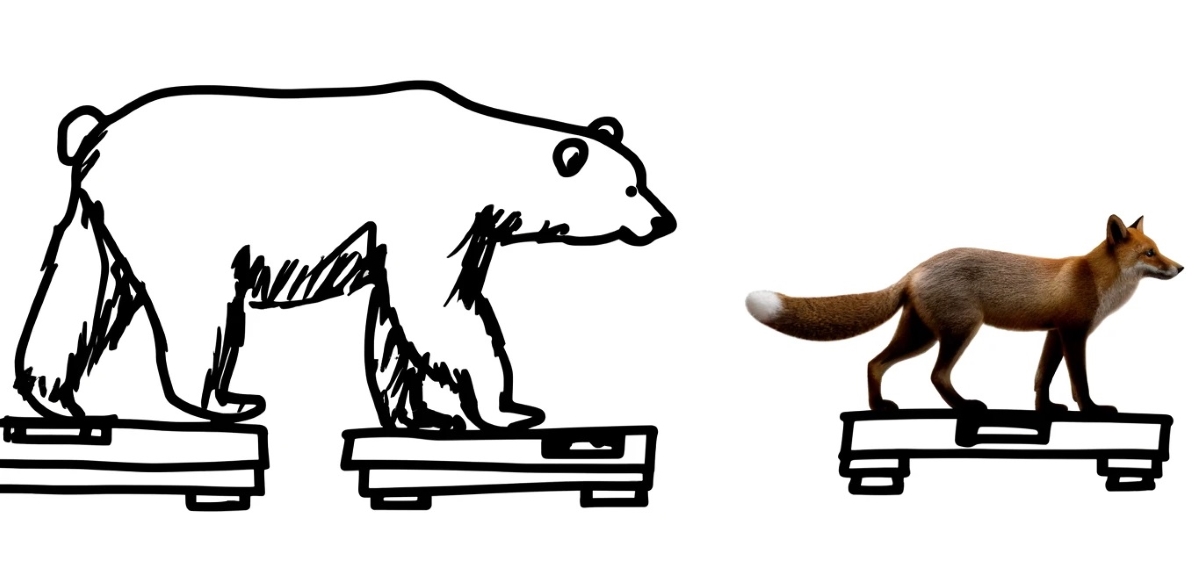

Mounting: Proper mounting is critical to ensure accurate measurements. Sensors must be mounted on a stable platform, free from vibrations and other external forces that could affect readings.

Calibration: Initial calibration is required to set the sensor's baseline measurement. It often involves loading the sensor with known weights and adjusting the output to match accurately.

Integration with Automation Systems:

Wiring and Connectivity: Ensure that the sensor is correctly connected to the automation system. This includes setting up any necessary analog or digital interfaces.

Software Configuration: Program the automation system to read and interpret the data from the sensors. This may involve setting thresholds for alarms, data logging intervals, and integration with other process control elements.

Evaluating Sensor Accuracy

Regular Calibration:

Calibration is essential to maintain accuracy over time. Sensors should be recalibrated at regular intervals according to manufacturer recommendations or following any major impact or environmental change.

Performance Testing:

Repeatability Tests: Perform tests to check if the sensor gives the same reading under the same load conditions repeatedly.

Linearity Tests: Ensure the sensor output is linear across the full range of its capacity to maintain accuracy at different load levels.

Drift Tests: Monitor the sensor for any drift in readings over time, which can indicate sensor aging or environmental effects.

Statistical Analysis:

Use statistical methods to analyze the data from the sensor. Techniques such as regression analysis or standard deviation assessment can help identify inconsistencies and potential issues with sensor performance.

Benchmarking Against Standards:

Compare the sensor's performance against industry standards and certifications. This can help ensure that the sensor meets the necessary regulatory and safety requirements.

The selection and configuration of weight sensors in industrial automation systems are intricate processes that require careful consideration of application requirements and environmental factors. Accurate sensor selection and proper setup are vital for reliable measurements, which are crucial for maintaining product quality and operational efficiency in automated industrial environments. Regular evaluation and maintenance of sensor accuracy are equally important to ensure long-term reliability and precision.

Based on the questions you have asked us, we have attempted to discuss the topic of weight measurement and scales both socially and technically. Weight measurement has undoubtedly been one of the most important topics in known history. Throughout our lives, we are all involved in weight measurement in production, consumption, trade, art, sports, etc.

General Questions:

++ Weight standards

- What's the difference between mass and weight, and their measurement methods?

- How does gravity's acceleration affect an object's weight on different planets?

- What are the uses and accuracy factors of precision scales and balances in weight measurement?

- How does weight measurement help determine an object's density?

- How is an object's apparent weight underwater calculated and related to its actual weight?

Industrial Automation and Production:

- How is weight measurement and control integrated into industrial production, and its impact on efficiency?

- What role do automatic weight control systems play in quality control, and how do they improve product quality?

- How are weight sensors selected and configured in industrial automation, and their accuracy evaluated?

- What are the latest developments in weight measurement technologies for industrial automation?

- What software and tools are used for weight data analysis in industrial automation, and their impact on workflow?

For the General Public:

- How can I test the accuracy of home kitchen scales?

- Which bathroom scale is best for tracking body weight, and what are the differences between models?

- How can I accurately measure luggage weight for travel and comply with airline limits?

- What type of kitchen scale should I use for measuring food portion sizes for healthy eating?

- How can I determine if my children are at a healthy weight, and what methods should I use?

Historical

- Archimedes and "Eureka!

- What instruments were used for weight measurement in ancient times?

- What were the units of weight in ancient civilizations?

- How important was weight measurement in trade in ancient societies?

- How did the first scales for measuring weight work in ancient times?

- How were standards for weight measurement established in ancient times?

- What were some significant discoveries related to weight measurement in ancient history?

- What methods were used to prevent fraud in weight measurement in ancient times?

- What events can be considered turning points in the history of weight measurement?

- How were weight measurement units compared between different cultures in ancient times?

- What are some written sources about weight measurement in ancient history?

++ Weight measuring devices homepage

"These

questions often include those that may come to mind for many people

regarding 'Weight measurement.' Each user or student will

have their own specific questions depending on a particular situation or

application. The answers are not binding or entirely definitive. There is no objection to sharing our above article, citing it as a source. - Automation Mall Community, 02/2021"

Your shopping cart is empty!