How is weight measurement carried out in industrial production?

Hi everyone,

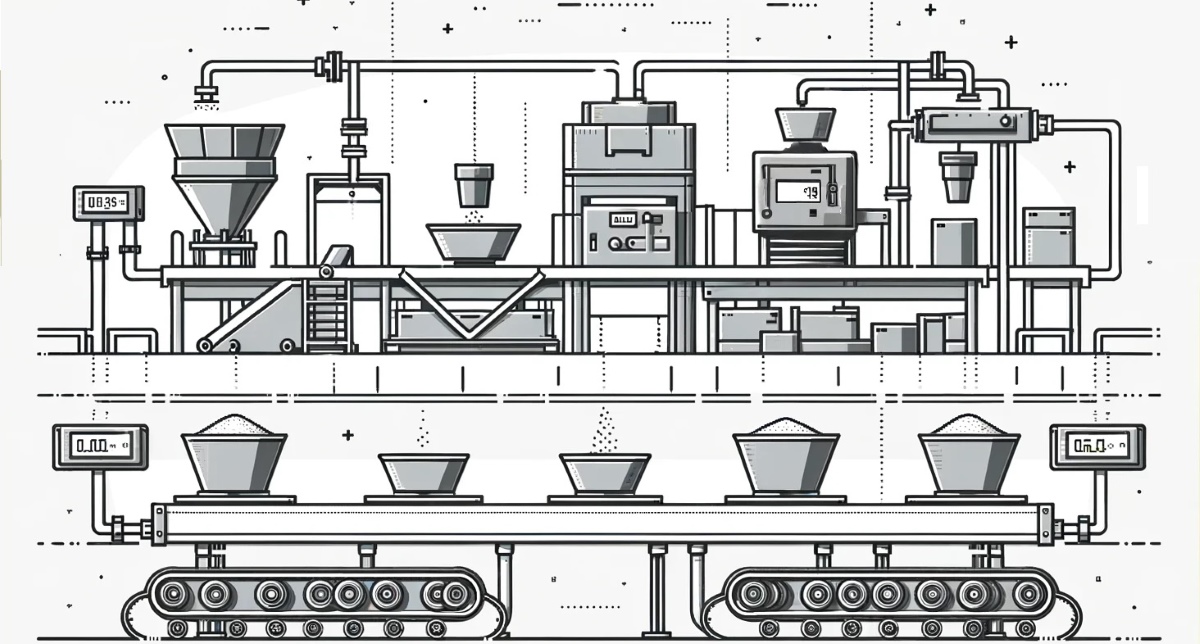

The integration of weight measurement and control systems into industrial production is a sophisticated process that enhances precision, efficiency, and quality control. This integration is particularly crucial in industries such as food and beverage, pharmaceuticals, and chemical manufacturing, where accurate measurements can directly affect product consistency, safety, and compliance with regulatory standards. Here’s a detailed exploration of how these systems are implemented and their impact on production efficiency:

Implementation of Weight Measurement and Control Systems

Selection of Appropriate Weighing Technology:

Balance Scales: Used for high precision requirements, such as in pharmaceutical preparations.

Load Cells: Employed in bulk material handling and packaging operations due to their ability to measure large quantities accurately.

Continuous Weighing Systems: Such as weigh belts and screw feeders, used in continuous production processes.

Integration into Production Lines:

Direct Integration: Weighing systems are built into production lines where ingredients or components are added. This setup allows for real-time measurement and adjustments.

Batch Integration: Used in batch processing industries, where ingredients are measured and mixed in batches. Control systems adjust the quantities based on the weight data to ensure consistent batch quality.

Data Connectivity and Process Automation:

SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems collect data from weight sensors and integrate it with other production data.

ERP Integration: Weight data is often integrated with Enterprise Resource Planning (ERP) systems to improve inventory management and traceability.

Feedback Loops: Automated feedback mechanisms adjust the material flow based on real-time weight data to maintain product consistency.

Calibration and Maintenance:

Regular calibration ensures the accuracy of weighing systems. Maintenance checks are scheduled to prevent downtime and equipment failure.

Impact on Production Efficiency

Enhanced Quality Control:

Consistency: Automated weight checks ensure that each product batch meets predetermined standards, reducing variability.

Compliance: Accurate weighing helps in adhering to strict industry regulations, avoiding costly recalls and fines.

Reduction in Waste:

Precise Ingredient Use: Accurate measurements mean exactly the right amount of ingredients is used, reducing excess.

Re-work Reduction: Proper initial measurements decrease the need for re-working batches, which can be costly and time-consuming.

Increased Throughput:

Speed: Automated systems enable faster weighing and adjustments, speeding up the production process.

Downtime Reduction: With advanced diagnostics and real-time monitoring, systems can predict and prevent potential failures, reducing downtime.

Improved Resource Management:

Material Savings: Precise control over material use leads to significant savings and more efficient use of resources.

Labor Efficiency: Automation of weighing and adjusting processes reduces the labor required, allowing staff to focus on higher-value activities.

Data-Driven Decision Making:

Trend Analysis: Continuous collection of weight data allows for analysis of production trends, helping to optimize processes.

Predictive Maintenance: Weight data combined with other sensor data can predict equipment failures before they occur, allowing for proactive maintenance.

Challenges and Considerations

Technological Integration:

Integrating new systems with existing production lines can be complex and requires careful planning to minimize disruption.

Cost:

The initial investment in high-quality weighing and control systems can be substantial, though the long-term savings often justify the expense.

Training and Adaptation:

Staff may require training to operate new systems effectively, and there can be a period of adjustment as processes are refined.

In conclusion, the integration of weight measurement and control systems into industrial production not only enhances the efficiency and quality of the production process but also contributes to better compliance, reduced waste, and more informed management decisions. As industries continue to evolve, the role of such advanced systems is likely to become even more integral to achieving high standards of production and operational excellence.

Based on the questions you have asked us, we have attempted to discuss the topic of weight measurement and scales both socially and technically. Weight measurement has undoubtedly been one of the most important topics in known history. Throughout our lives, we are all involved in weight measurement in production, consumption, trade, art, sports, etc.

General Questions:

++ Weight standards

- What's the difference between mass and weight, and their measurement methods?

- How does gravity's acceleration affect an object's weight on different planets?

- What are the uses and accuracy factors of precision scales and balances in weight measurement?

- How does weight measurement help determine an object's density?

- How is an object's apparent weight underwater calculated and related to its actual weight?

Industrial Automation and Production:

- How is weight measurement and control integrated into industrial production, and its impact on efficiency?

- What role do automatic weight control systems play in quality control, and how do they improve product quality?

- How are weight sensors selected and configured in industrial automation, and their accuracy evaluated?

- What are the latest developments in weight measurement technologies for industrial automation?

- What software and tools are used for weight data analysis in industrial automation, and their impact on workflow?

For the General Public:

- How can I test the accuracy of home kitchen scales?

- Which bathroom scale is best for tracking body weight, and what are the differences between models?

- How can I accurately measure luggage weight for travel and comply with airline limits?

- What type of kitchen scale should I use for measuring food portion sizes for healthy eating?

- How can I determine if my children are at a healthy weight, and what methods should I use?

Historical

- Archimedes and "Eureka!

- What instruments were used for weight measurement in ancient times?

- What were the units of weight in ancient civilizations?

- How important was weight measurement in trade in ancient societies?

- How did the first scales for measuring weight work in ancient times?

- How were standards for weight measurement established in ancient times?

- What were some significant discoveries related to weight measurement in ancient history?

- What methods were used to prevent fraud in weight measurement in ancient times?

- What events can be considered turning points in the history of weight measurement?

- How were weight measurement units compared between different cultures in ancient times?

- What are some written sources about weight measurement in ancient history?

++ Weight measuring devices homepage

"These

questions often include those that may come to mind for many people

regarding 'Weight measurement.' Each user or student will

have their own specific questions depending on a particular situation or

application. The answers are not binding or entirely definitive. There is no objection to sharing our above article, citing it as a source. - Automation Mall Community, 02/2021"

Your shopping cart is empty!