Safety features are included in DC drives?

Hello DC Control friends,

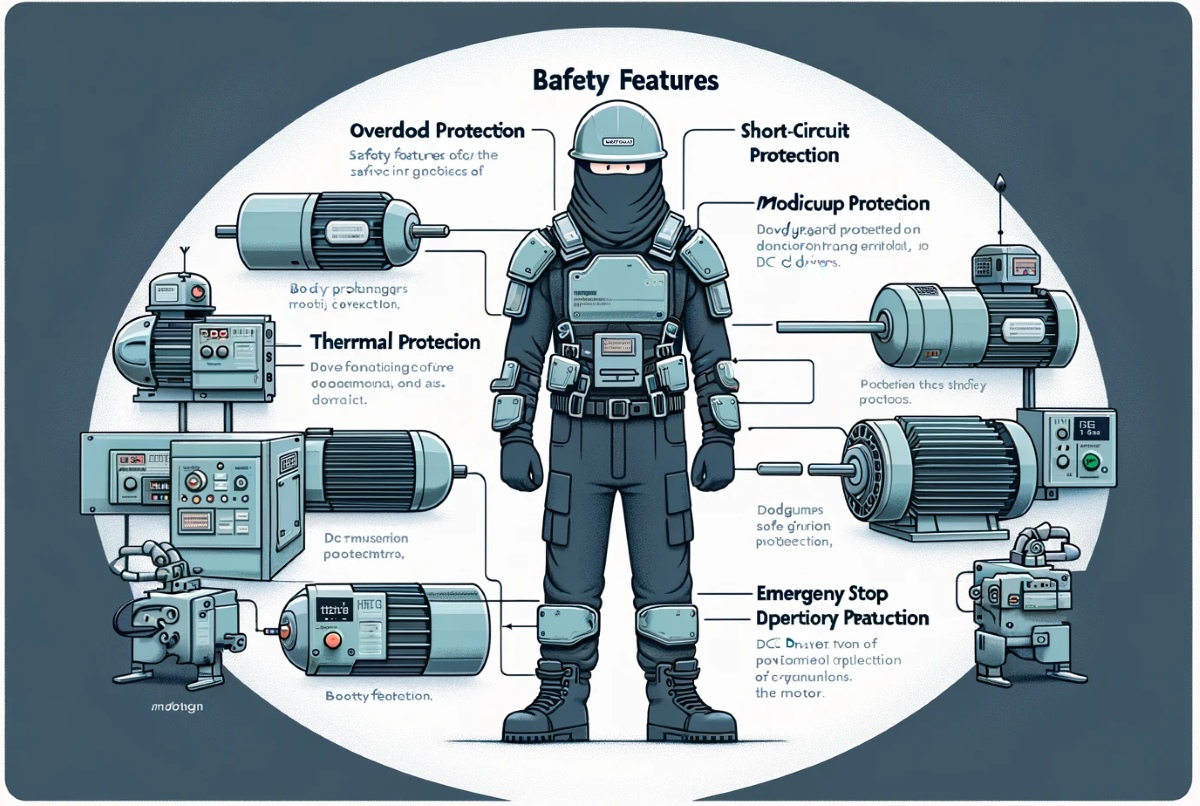

The safety features integrated into DC drives can vary based on the manufacturer and model, as well as the specific application requirements. However, some common safety features you might expect to find include:

Electrical Safety Features

Overload Protection: To protect the motor and the drive from damage due to excessive load.

Short Circuit Protection: To safeguard against short-circuit conditions that can damage the drive.

Overvoltage and Undervoltage Protection: To protect the drive from voltage fluctuations in the supply.

Phase Loss Protection: To safeguard against the loss of one or more supply phases.

Operational Safety Features

Emergency Stop: A function to quickly stop the motor in case of an emergency.

Safe Torque Off (STO): A feature to safely remove power from the motor to prevent unexpected starts.

Speed Limiting: To ensure the motor doesn’t exceed a predefined speed.

Brake Control: Effective brake control for applications that require rapid or controlled stops.

Directional Locks: To prevent the motor from running in the wrong direction.

Monitoring and Diagnostic Features

Temperature Monitoring: To prevent overheating of the drive and/or motor.

Status Indicators: LEDs or display screens that show the operational status, errors, or warnings.

Data Logging: For recording operational data that can help in diagnostics and maintenance.

Communication Safety

Safe Communication Protocols: Some drives offer safe communication options that adhere to industrial safety standards.

Password Protection: To prevent unauthorized access and changes to the drive settings.

Additional Safety Features

Isolation: Electrical isolation features to separate drive circuits and protect users.

Ground Fault Protection: To detect any imbalance in the electrical current.

Certifications

Most modern DC drives come with safety certifications like CE, UL, or ISO to indicate compliance with international safety standards.

Understanding the safety features that come with a specific DC drive model can help you make a more informed decision when choosing a drive for your application. Always consult the manufacturer’s technical specifications and documentation for detailed information on safety features.

While the use of DC drives in industry (at least at high power levels) has diminished, they are still widely found. Below, we have attempted to answer the most frequently asked questions about DC drives from our visitors.

- What are the operating principles of DC drives?

- What are the different types of DC drives?

- What are the key differences between DC drives and AC drives?

- What are the typical applications for DC drives?

- How energy-efficient are DC drives?

- What are the control methods used in DC drives?

- What type of DC drive is most suitable for a specific DC motor?

- What are the most common problems and solutions associated with DC drives?

- What are the power ranges used in DC drives?

- What additional components are used alongside DC drives?

- What are the advantages and disadvantages of DC drives?

- How do I choose a DC drive?

- How scalable are DC drives?

- Is integration between a DC drive and a PLC possible?

- What are the lifespan and maintenance requirements for DC drives?

- What safety features are included in DC drives?

- How is the dynamic response in DC drives?

- What feedback options are available in DC drives?

- What types of protection mechanisms are used in DC drives?

- What types of sensors can be used with DC drives?

These questions generally also encompass the types of queries that many people may have about DC drives. Each user or student will have their own unique question or interpretation depending on the specific situation or application. The answers provided are not binding and are not definitive. "You are welcome to share the article above as long as you cite it as the source." 05.2019

Your shopping cart is empty!