What types of sensors can be used with DC drives?

Hello DC Control friends,

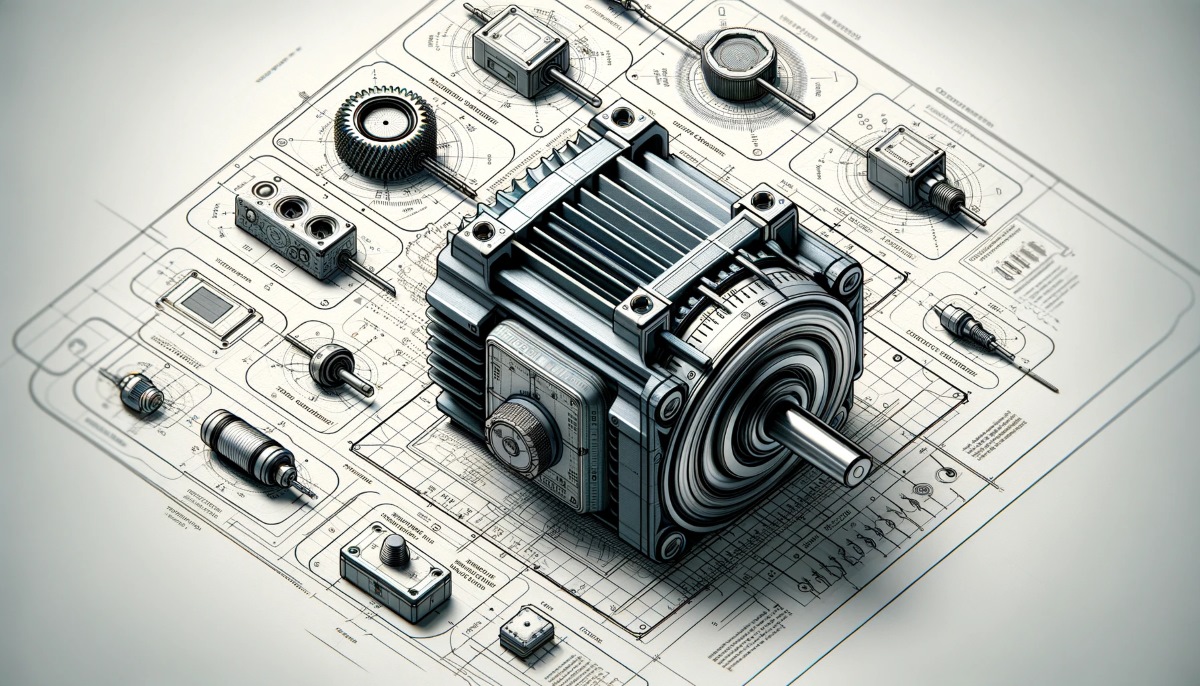

Sensors play a vital role in the functioning of DC drives, providing the necessary feedback for control and monitoring. Various types of sensors can be used in conjunction with DC drives, depending on the specific application and requirements:

Speed Sensors

Tachometers: These are commonly used for speed feedback and help in maintaining constant speed.

Encoders: Optical or magnetic encoders can provide precise speed and sometimes position feedback.

Current Sensors

Hall-effect sensors: These are used to measure the current flowing through the motor windings.

Current transformers: These can also be used to sense the current level for higher-power applications.

Voltage Sensors

These are used to monitor the voltage levels in the system and may trigger protective mechanisms if abnormal levels are detected.

Position Sensors

Potentiometers: These can be used for basic position feedback.

Encoders: As mentioned above, some encoders can provide both speed and position feedback.

Resolvers: These are less common but provide high-resolution position feedback.

Temperature Sensors

Thermistors or RTDs: These can be embedded in the motor windings to monitor temperature.

Infrared Sensors: These can be used for remote temperature monitoring.

Torque Sensors

Strain gauges can be used to measure the motor shaft torque directly.

Vibration Sensors

Accelerometers can be used to monitor vibrations in the motor or associated machinery.

Proximity Sensors

Inductive or capacitive sensors can be used to detect the presence or absence of an object or material.

Pressure Sensors

These can be used in hydraulic systems that may be integrated with the DC motor for specific applications like pressing or lifting.

Optical Sensors

These can be used for detecting parameters like distance, presence, or absence of objects, and can also help in speed detection in some cases.

Communication Sensors

Some advanced DC drives may use Ethernet or other communication protocols to receive sensor data from a centralized control system.

Each type of sensor has its advantages and disadvantages, and the choice of sensor would depend on the specific requirements of your application, such as the level of precision, environmental conditions, and budget constraints. Always consult the DC drive manufacturer's guidelines or experts in the field to determine the most suitable sensors for your system.

While the use of DC drives in industry (at least at high power levels) has diminished, they are still widely found. Below, we have attempted to answer the most frequently asked questions about DC drives from our visitors.

- What are the operating principles of DC drives?

- What are the different types of DC drives?

- What are the key differences between DC drives and AC drives?

- What are the typical applications for DC drives?

- How energy-efficient are DC drives?

- What are the control methods used in DC drives?

- What type of DC drive is most suitable for a specific DC motor?

- What are the most common problems and solutions associated with DC drives?

- What are the power ranges used in DC drives?

- What additional components are used alongside DC drives?

- What are the advantages and disadvantages of DC drives?

- How do I choose a DC drive?

- How scalable are DC drives?

- Is integration between a DC drive and a PLC possible?

- What are the lifespan and maintenance requirements for DC drives?

- What safety features are included in DC drives?

- How is the dynamic response in DC drives?

- What feedback options are available in DC drives?

- What types of protection mechanisms are used in DC drives?

- What types of sensors can be used with DC drives?

These questions generally also encompass the types of queries that many people may have about DC drives. Each user or student will have their own unique question or interpretation depending on the specific situation or application. The answers provided are not binding and are not definitive. "You are welcome to share the article above as long as you cite it as the source." 05.2019

Your shopping cart is empty!