PID Control for Temperature

Hello dear colleagues,

PID control is a widely used technique in temperature control systems, offering a balance between precision and simplicity. PID stands for Proportional, Integral, and Derivative, which are the three basic components of this control method. Each component serves a different purpose and together they provide a comprehensive control strategy.

Proportional Control (P)

The proportional component depends on the current error, which is the difference between the desired setpoint and the actual temperature. The proportional gain (Kp) determines how aggressively the controller reacts to this error. A higher Kp value leads to a faster response, but it can also cause overshoot and oscillations around the setpoint.

Integral Control (I)

The integral component is concerned with the accumulation of past errors. It aims to eliminate the steady-state error that can occur with proportional control alone. The integral gain (Ki) determines how strongly the controller reacts to the accumulated error. If Ki is too high, it can lead to instability and oscillations.

Derivative Control (D)

The derivative component predicts future errors based on the rate of change of the error. It provides a damping effect, helping to reduce overshoot and improve stability. The derivative gain (Kd) determines the impact of this component. However, in temperature control systems, the derivative term is often omitted or used cautiously due to its sensitivity to noise.

Tuning PID Parameters

Tuning the PID parameters (Kp, Ki, Kd) is crucial for optimal performance. There are various methods for tuning, including manual tuning, Ziegler-Nichols method, Cohen-Coon method, and software-based optimization techniques. The goal is to find a balance between responsiveness and stability, minimizing overshoot and settling time.

Implementation in Temperature Control

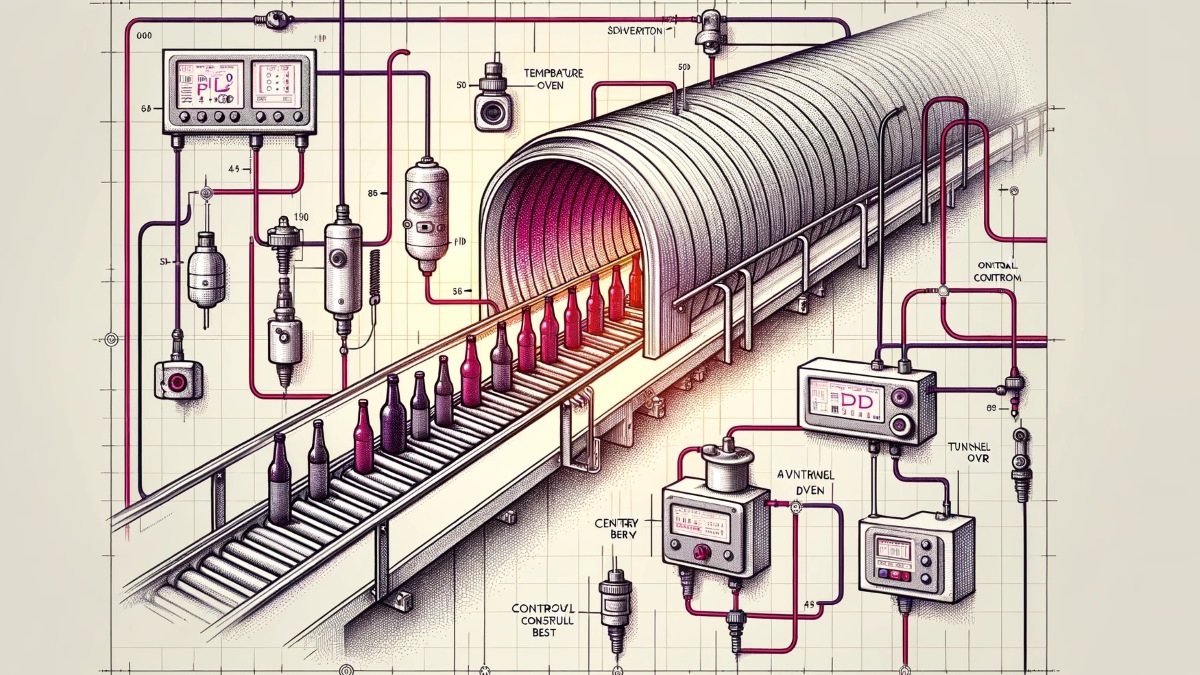

In a temperature control system, the PID controller continuously calculates the error and adjusts the control output (e.g., the power supplied to a heater) to maintain the desired temperature. The system might include sensors for temperature measurement, actuators for heating or cooling, and a feedback loop to adjust the control output based on the PID algorithm.

Challenges and Considerations

- Sensor Accuracy: The precision of temperature sensors directly impacts the effectiveness of PID control.

- System Dynamics: The response time and dynamics of the heating/cooling elements affect the tuning of PID parameters.

- External Disturbances: Variations in environmental conditions or external heat sources can influence temperature control.

- Nonlinearity: Temperature control systems can exhibit nonlinear behavior, complicating the tuning process.

PID control is a versatile and effective method for temperature control, offering a balance between simplicity and precision. Proper tuning of the PID parameters is essential for achieving optimal performance, and understanding the dynamics of the specific system is crucial for successful implementation.

One of the most commonly used control methods in industrial automation, production, and control systems is undoubtedly the PID Control format. We have sought answers to your questions about this control type, which has made the job of our software developer friends perfectly easy many times.

- What is PID?

- What do the components of the PID control algorithm (P, I, D) mean?

- What are the limitations of the PID control algorithm?

- PID control and stable operation?

- What are the common problems with PID controllers?

- How does a PID controller work?

- How are the parameters (Kp, Ki, Kd) in a PID controller adjusted?

- The time factor in setting PID parameters?

- How should PID control parameters be set for different types of processes?

- What are the differences between PID and other control strategies?

- PID Control with PLC

- PID Control with Raspberry Pi

- PID Control with Robotics

- PID Control with SCADA

- PID Control with Servo Motor

- PID control with VFD

- PID Control with Temperature Control Device

- PID Control with Arduino

- Cloud-Based PID Control

- PID Control with Industrial PC

- PID Control with FPGA

- Real-time PID control?

- PID Control with Microprocessor

- PID Control with Current Control

- PID Control with Flow Control

- PID Control with Pressure Control

- PID Control with Frequency Control

- PID Control with Power Control

- PID Control with Speed Control

- PID Control with Temperature Control

- PID Control with Light Control

- PID Control with Smell Control

- PID Control with Humidity Control

- PID Control with pH Control

- PID Control with Position Control

- PID Control with Radiation Control

- PID Control with Color Control

- PID Control with Sound Control

- PID Control with Level Control

- PID Control with Vibration Control

- PID Control with Torque Control

- PID Control with Viscosity Control

- PID Control with Density Control

++ Automation Homepage

"These

questions include questions that many people might think of on the

subject of 'PID Control and details.' Each user or student will have

their own specific questions depending on a particular situation or

application. The answers are not binding or completely definitive.

'There is no harm in sharing our article above by citing it as a

source.'" 11/2022

Your shopping cart is empty!