What do the (P, I, D) of the PID algorithm mean?

Hello dear colleagues,

What do the basic components of a PID control algorithm (P, I, D) mean and how does each contribute to the control process?

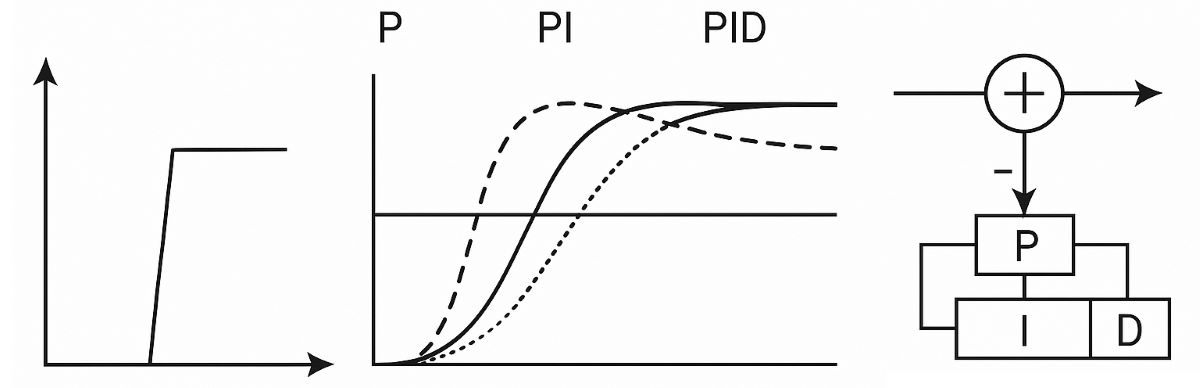

The Proportional-Integral-Derivative (PID) control algorithm is a widely used control strategy in industrial automation and process control. It consists of three basic components: Proportional (P), Integral (I), and Derivative (D), each contributing differently to the control process. Understanding the meaning and function of each component is essential for designing and tuning PID controllers effectively.

Proportional (P) Component:

Meaning: The proportional component is responsible for providing an immediate response to the error, which is the difference between the setpoint (desired value) and the process variable (measured value).

Function: The proportional term generates a control output that is proportional to the error. The proportionality constant, known as the proportional gain (Kp), determines the strength of the response. A higher Kp results in a larger control action for a given error, leading to a faster response. However, excessive Kp can cause overshoot and oscillations.

Integral (I) Component:

Meaning: The integral component addresses the accumulated error over time, helping to eliminate any steady-state error (offset) that remains after the initial response.

Function: The integral term sums up the error over time and generates a control output that is proportional to the total accumulated error. The integral gain (Ki) determines how quickly the integral action accumulates. A higher Ki increases the impact of the integral term, reducing steady-state error but potentially leading to overshoot and slower response times.

Derivative (D) Component:

Meaning: The derivative component predicts future errors based on the rate of change of the error, providing a damping effect that helps to reduce overshoot and improve stability.

Function: The derivative term calculates the rate of change of the error and generates a control output that is proportional to this rate. The derivative gain (Kd) determines the impact of the derivative action. A higher Kd enhances the damping effect, reducing overshoot and settling time. However, excessive Kd can make the system sensitive to noise and lead to erratic control actions.

Overall Contribution to Control Process:

Proportional Term: Provides immediate response to errors, determining the system's responsiveness.

Integral Term: Eliminates steady-state error, ensuring that the process variable reaches and maintains the setpoint.

Derivative Term: Dampens oscillations and improves stability, reducing overshoot and settling time.

In summary, the PID control algorithm combines the effects of the proportional, integral, and derivative components to provide a control output that adjusts the process variable towards the setpoint. The proportional term responds to the present error, the integral term corrects past errors, and the derivative term anticipates future errors. The proper tuning of the PID gains (Kp, Ki, Kd) is crucial to achieve the desired control performance, balancing responsiveness, stability, and steady-state accuracy.

One of the most commonly used control methods in industrial automation, production, and control systems is undoubtedly the PID Control format. We have sought answers to your questions about this control type, which has made the job of our software developer friends perfectly easy many times.

- What is PID?

- What do the components of the PID control algorithm (P, I, D) mean?

- What are the limitations of the PID control algorithm?

- PID control and stable operation?

- What are the common problems with PID controllers?

- How does a PID controller work?

- How are the parameters (Kp, Ki, Kd) in a PID controller adjusted?

- The time factor in setting PID parameters?

- How should PID control parameters be set for different types of processes?

- What are the differences between PID and other control strategies?

- PID Control with PLC

- PID Control with Raspberry Pi

- PID Control with Robotics

- PID Control with SCADA

- PID Control with Servo Motor

- PID control with VFD

- PID Control with Temperature Control Device

- PID Control with Arduino

- Cloud-Based PID Control

- PID Control with Industrial PC

- PID Control with FPGA

- Real-time PID control?

- PID Control with Microprocessor

- PID Control with Current Control

- PID Control with Flow Control

- PID Control with Pressure Control

- PID Control with Frequency Control

- PID Control with Power Control

- PID Control with Speed Control

- PID Control with Temperature Control

- PID Control with Light Control

- PID Control with Smell Control

- PID Control with Humidity Control

- PID Control with pH Control

- PID Control with Position Control

- PID Control with Radiation Control

- PID Control with Color Control

- PID Control with Sound Control

- PID Control with Level Control

- PID Control with Vibration Control

- PID Control with Torque Control

- PID Control with Viscosity Control

- PID Control with Density Control

++ Automation Homepage

"These

questions include questions that many people might think of on the

subject of 'PID Control and details.' Each user or student will have

their own specific questions depending on a particular situation or

application. The answers are not binding or completely definitive.

'There is no harm in sharing our article above by citing it as a

source.'" 11/2022

Your shopping cart is empty!