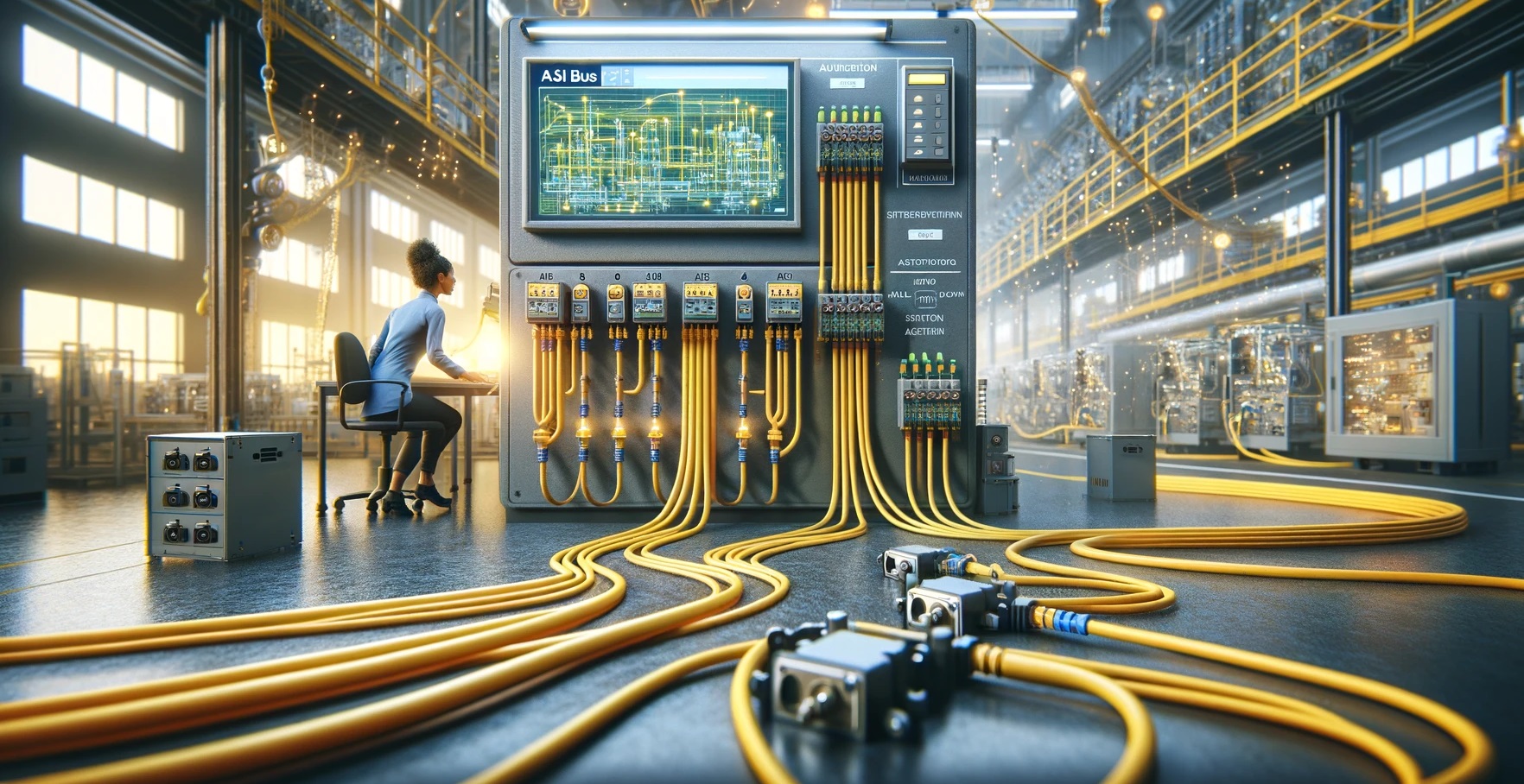

What is ASI BUS (As-interface)?

AS-i bus (AS-Interface) is a communication protocol and bus system used in industrial automation and control systems. It stands for "Actuator-Sensor Interface" and is used to connect sensors and actuators in a distributed control system. It is a low-cost, low-maintenance, and easy-to-use solution for connecting devices on a factory floor or in a building automation system. The AS-i bus uses a simple, two-wire connection to transmit data between devices, and supports up to 62 devices on a single bus. It is often used in applications such as conveyor systems, packaging machinery, and machine tools.

What is an ASi device?

An AS-i (Actuator-Sensor Interface) device is a type of industrial control device that is connected to an AS-i bus. The AS-i bus is a communication protocol and bus system used in industrial automation and control systems. AS-i devices can include sensors, actuators, and other types of industrial control equipment that are connected to the bus to exchange data and control signals. Examples of AS-i devices include proximity sensors, limit switches, valve actuators, and motor controllers. These devices can be connected to the bus using a simple, two-wire connection, and can communicate with each other to exchange data and control signals.

How does as I bus communication work?

AS-i (Actuator-Sensor Interface) bus communication works by transmitting data over a two-wire bus using a proprietary protocol. The bus is composed of a master device, which is responsible for controlling the communication on the bus, and one or more slave devices, which are connected to the bus and communicate with the master.

Data is transmitted in the form of frames, which consist of a start bit, an address field, a data field, and a checksum. The master device initiates communication by sending a request frame to a slave device, which responds with a response frame containing the requested data. The master device can also send command frames to the slave devices to control their behavior.

The AS-i bus uses a simple, two-wire connection to transmit data between devices, one wire for power supply and the other for data transmission. This simple and cheap wiring is one of the main advantages of the AS-i bus. The bus supports up to 62 devices on a single bus and operates at 31.25 kbps.

Additionally, the AS-i protocol is designed to be self-monitoring, meaning it detects and reports communication errors, such as short-circuits, open circuits, and device failures, which makes it a reliable and maintenance-friendly solution for industrial control systems.

What are the uses ASi?

AS-i (Actuator-Sensor Interface) is widely used in industrial automation and control systems for a variety of applications. Some of the main uses of AS-i include:

Conveyor systems: AS-i is often used to connect sensors and actuators on conveyor systems to monitor and control the movement of materials.

Packaging machinery: AS-i is used to connect sensors and actuators on packaging machinery, such as filling machines and labeling machines, to monitor and control the packaging process.

Machine tools: AS-i is used to connect sensors and actuators on machine tools, such as lathes and milling machines, to monitor and control the machining process.

Building automation: AS-i can be used in building automation systems to connect sensors and actuators for monitoring and controlling various functions such as lighting, HVAC, and security systems.

Automotive: AS-i can be used in automotive applications to connect sensors and actuators on machines like assembly lines, test stands and control systems.

Robotics: AS-i can be used to connect sensors and actuators on robots, allowing for precise control and monitoring of their movement and actions.

Safety systems: AS-i can be used in safety systems to connect sensors and actuators to detect and respond to potential hazards.

Overall, AS-i is a versatile and cost-effective solution that can be used in a wide range of industrial and building automation applications to connect and control various types of devices.

ASi bus vs profibus

AS-i (Actuator-Sensor Interface) bus and PROFIBUS (Process Field Bus) are both communication protocols and bus systems used in industrial automation and control systems, but they have some significant differences:

Purpose: AS-i is designed to connect simple sensors and actuators, such as proximity sensors and valve actuators, in a distributed control system. PROFIBUS, on the other hand, is designed to connect a wide range of devices, including programmable controllers, drives, and I/O modules, in a more complex automation system.

Topology: AS-i uses a simple, two-wire bus that supports up to 62 devices on a single bus. PROFIBUS, on the other hand, uses a multi-drop bus topology and can support up to 126 devices per bus.

Data rate: AS-i operates at 31.25 kbps, while PROFIBUS can operate at several different data rates, including 9.6 kbps, 19.2 kbps, and 12 Mbps.

Networking capabilities: AS-i is not designed for networking, while PROFIBUS can connect multiple devices over a wide area network.

Cost: AS-i is a low-cost solution, while PROFIBUS is more expensive due to its more complex technology and capabilities.

In summary, AS-i is a simple and cost-effective solution for connecting sensors and actuators in a distributed control system, while PROFIBUS is a more powerful and versatile solution for connecting a wide range of devices in a more complex automation system.

Your shopping cart is empty!