what is BLDC motor?

BLDC motor stands for Brushless DC Motor. These motors operate on DC power sources and do not have brushes as components that wear out. BLDC motors are used in a variety of industrial applications and are typically air-cooled.

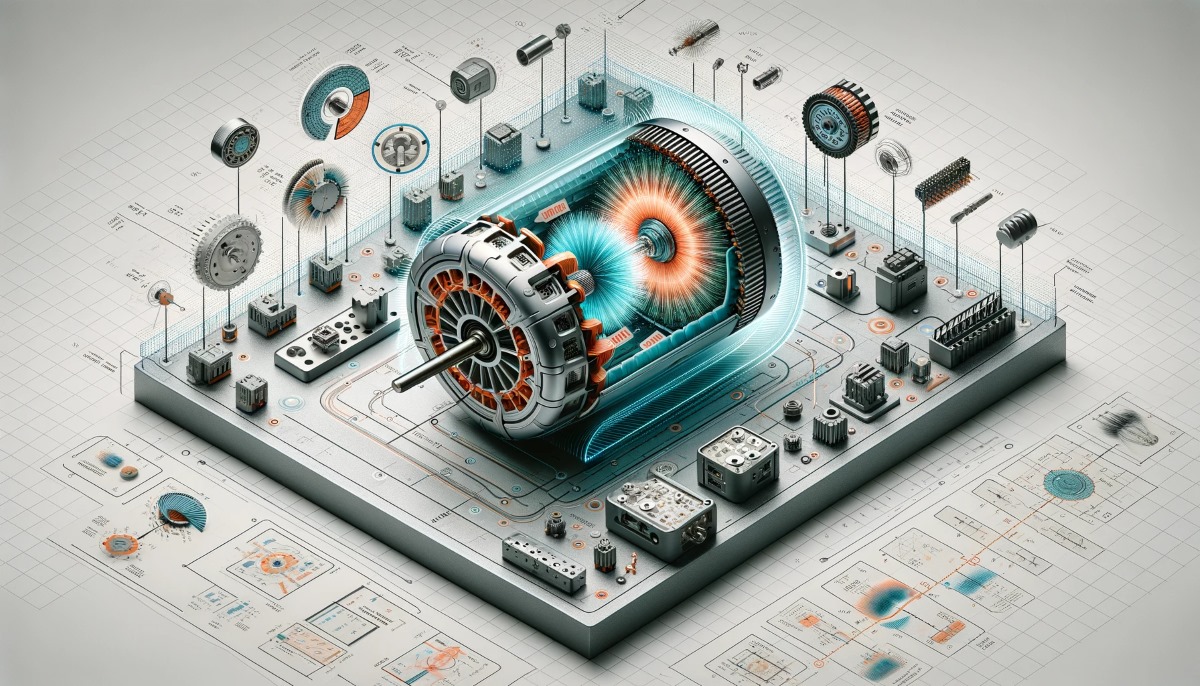

BLDC motors have a three-phase structure and are composed of two main parts: the rotor and the stator. The stator remains stationary and the rotor rotates based on it. The rotor is a wheel that surrounds the stator and drives it to rotate. As the rotor rotates the stator, an electromechanical force is generated through the coils surrounding the stator and the motor starts to operate.

BLDC motors have many advantages. They operate with low levels of noise and vibration and can be easily controlled. They also have high efficiencies and require little maintenance. They are also long-lasting. These characteristics make BLDC motors a popular choice in industrial applications.

How does BLDC motor work?

A BLDC motor works by using an electronic controller to energize the stator windings in a specific sequence, causing the rotor to rotate. The electronic controller uses sensor feedback to determine the position of the rotor and applies the appropriate current to the stator windings to keep the rotor moving.

The stator of a BLDC motor is made up of a series of windings, or coils, that are connected to an external power source. The rotor is a magnetically charged wheel that rotates around the stator. As the stator windings are energized, an electromagnetic field is created, which causes the rotor to rotate.

The rotation of the rotor is controlled by the electronic controller, which uses sensors to detect the position of the rotor and applies the appropriate current to the stator windings. This process is known as "commutation." The electronic controller continuously monitors the position of the rotor and adjusts the current to the stator windings to keep the rotor moving.

The speed of the BLDC motor is controlled by the frequency of the current applied to the stator windings. The torque of the motor is controlled by the magnitude of the current applied to the stator windings. By adjusting the frequency and magnitude of the current applied to the stator windings, the electronic controller can fine-tune the performance of the BLDC motor.

What is difference between normal DC motor and BLDC motor?

There are several key differences between a normal DC motor and a BLDC motor:

Construction: A normal DC motor has a brush and commutator system to transfer power to the rotor, while a BLDC motor does not have brushes or a commutator. Instead, it uses an electronic controller to transfer power to the rotor.

Power source: A normal DC motor can operate on either AC or DC power, while a BLDC motor can only operate on DC power.

Control: A normal DC motor is controlled by adjusting the voltage applied to the motor, while a BLDC motor is controlled by adjusting the frequency and magnitude of the current applied to the stator windings.

Efficiency: BLDC motors are typically more efficient than normal DC motors because they do not have brushes or a commutator, which can cause energy losses.

Maintenance: BLDC motors require less maintenance than normal DC motors because they do not have brushes or a commutator, which wear out over time.

Noise and vibration: BLDC motors operate with lower levels of noise and vibration than normal DC motors because they do not have brushes or a commutator.

Overall, BLDC motors are more efficient, require less maintenance, and operate with lower levels of noise and vibration than normal DC motors. However, they can only operate on DC power and are more expensive to manufacture.

BLDC motor drive?

A BLDC motor drive, also known as a "brushless DC motor driver," is a device used to control the operation of a brushless DC motor. The BLDC motor drive senses the position of the rotor of the motor through sensors and provides the electrical current needed to drive the rotor.

The BLDC motor drive is used to control the speed and torque of the motor. It also optimizes the operating conditions of the motor and prevents damage during operation. The BLDC motor drive reduces the heat generated by the motor during operation and increases the efficiency of the motor.

BLDC motor drives are used in a variety of industrial applications and are typically air-cooled. They have many advantages, including being easily programmable and controllable, and having high efficiency and long lifetimes. These characteristics make BLDC motor drives a popular choice in industrial applications.

BLDC motor avangate vs disavangate

BLDC motors are a type of brushless DC motor that are used in a variety of industrial applications. They have many advantages and disadvantages:

Advantages:

Low noise level: BLDC motors operate with a low noise level and are therefore preferred in industrial applications.

Low vibration level: BLDC motors operate with a low vibration level and are therefore preferred in industrial applications.

Easy control: BLDC motors are easily controllable and are therefore preferred in industrial applications.

High efficiency: BLDC motors operate with high efficiency and are therefore preferred in industrial applications.

Low maintenance: BLDC motors require low maintenance and are therefore preferred in industrial applications.

Long lifespan: BLDC motors have a long lifespan and are therefore preferred in industrial applications.

Disadvantages:

High cost: BLDC motors may be more expensive than other types of motors.

High starting current: BLDC motors may have a higher starting current than other types of motors.

Requires a control device: BLDC motors require a control device to operate, which can add an additional cost.

Requires more electronic circuitry: BLDC motors require more electronic circuitry to operate, which can add an additional cost.

Overall, BLDC motors are preferred in industrial applications due to their low noise and vibration levels, easy control, high efficiency, low maintenance, and long lifespan. However, they may be more expensive and require a control device and additional electronic circuitry.

"Despite a decline in their industrial use (at least for high-power applications), DC motors are still commonly found. However, they continue to be efficiently used in lower power applications. Below, we have attempted to answer the most frequently asked questions about DC drives by our visitors.

- What are the types of DC motors?

- What is a brushless DC (BDCL) motor?

- What are the advantages of DC motors?

- DC Motors and Efficiency Ratio?

- Can DC motors reach high speeds?

- What is its lifespan of a DC Motor?

- How does it differ from AC motors?

- What is the maintenance for DC motors?

- What is DC Drive?

+ Back to DC Motor Homepage -

These questions often encompass the types of queries that many people might have about DC motors. Every user or student will have their own unique questions or interpretations depending on the specific situation or application. The answers provided are not binding and are not definitive. 'Feel free to share the above article, citing it as a source.' 05.2019

Your shopping cart is empty!