How is security ensured in PLC systems?

Hi everyone,

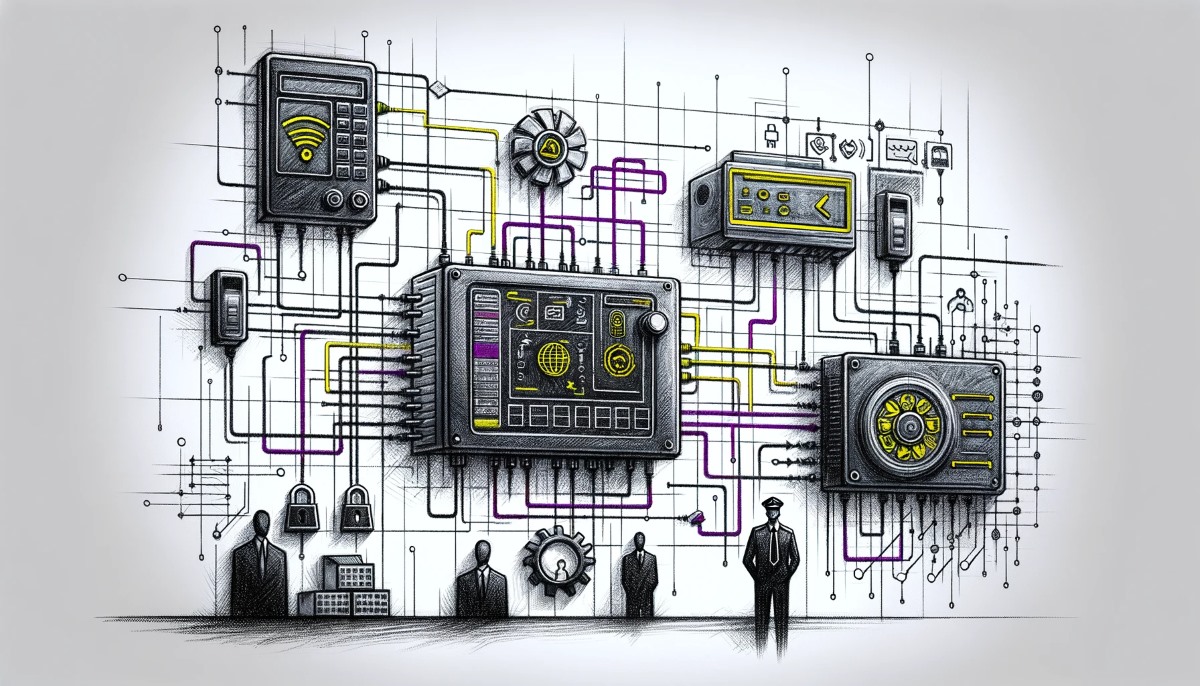

Ensuring security in PLC (Programmable Logic Controller) systems involves a combination of hardware, software, and network security measures. The following steps can help improve the security of a PLC system:

Access Controls: It's crucial to have robust access controls for any PLC system. This often involves the use of unique usernames and passwords, or even more secure methods such as two-factor authentication.

Physical Security: Physical access to the PLC system should be tightly controlled. This means that the PLC hardware should be stored in a secure location, and only authorized personnel should be allowed access.

Firewalls and Intrusion Detection Systems (IDS): Firewalls should be used to help prevent unauthorized access to the network the PLC is connected to. Intrusion Detection Systems can be used to monitor the network for any unusual activity, such as attempts to access the PLC system.

Encryption: Data sent to and from the PLC should be encrypted to help protect it from interception. This is especially important for wireless communication, but is also relevant for wired connections.

Regular Updates and Patches: Just like any other software system, the software on a PLC needs to be kept up-to-date. Regular updates and patches can help to fix any security vulnerabilities that may have been discovered.

Security Audits: Regular security audits can help to identify any potential security issues and ensure that all necessary security measures are in place.

Network Segmentation: Separating the control network (where PLCs reside) from the enterprise network can help prevent cyber-attacks from spreading across the entire organization. This technique is known as network segmentation or network isolation.

Secure Coding Practices: PLC programmers should adhere to secure coding practices to avoid introducing vulnerabilities into the system.

Training and Awareness: Employees who work with or around the PLC system should be trained in basic cybersecurity practices. This can help to prevent many common types of cyberattacks, such as phishing.

The exact security measures required will vary depending on the specific PLC system and the environment in which it's being used. Also, as cybersecurity threats evolve, new techniques and practices will likely need to be adopted to maintain security.

++ What is Stuxnet and Iran nuclear incident?

Our visitors often ask the following types of questions about PLCs (Programmable Logic Controllers):

- What is a PLC and what are its primary functions?

- How are PLCs used in industrial automation?

- What are the differences between PLC programming languages like Ladder Logic, Structured Text, and Function Block Diagram?

- What software should I use to program a PLC? For instance, CoDeSys, TIA Portal, RSLogix, etc.

- What are the differences between various PLC brands and models? (e.g., Siemens, Allen-Bradley, Mitsubishi, Omron)

- How do input and output modules in a PLC work?

- What is the relationship between a PLC and SCADA? How do these two systems work together?

- How is debugging performed in PLCs? What are the troubleshooting techniques?

- How is security ensured in PLC systems?

- What are the future trends and developments in PLC technology? How do technologies like IoT, artificial intelligence, machine learning impact PLCs?

+ Back to PLC Main page -These questions also cover what many people generally might wonder about when it comes to PLCs. Each user or student will have their own specific questions depending on their particular situation or application. The answers are not binding or completely definitive.

Your shopping cart is empty!